For each good friend of customers, if we can effectively control the centrifugal fan mechanical equipment exhaust volume, we can get good benefits. First of all, the effective control of the centrifugal fan exhaust volume, can reflect the actual effect of mechanical equipment, but also help you reduce heat consumption, for you to save resources.

Before learning and training the appropriate adjustment method, we should know some relevant professional knowledge, so that we can know the following questions more quickly. Only by adjusting the exhaust air volume of centrifugal fan reasonably, can the true, real efficacy and use value of this special equipment be further embodied. Also can give our office environment a faster standard. Before that, we must know some major expertise in order to control the volume of exhaust air as soon as possible.

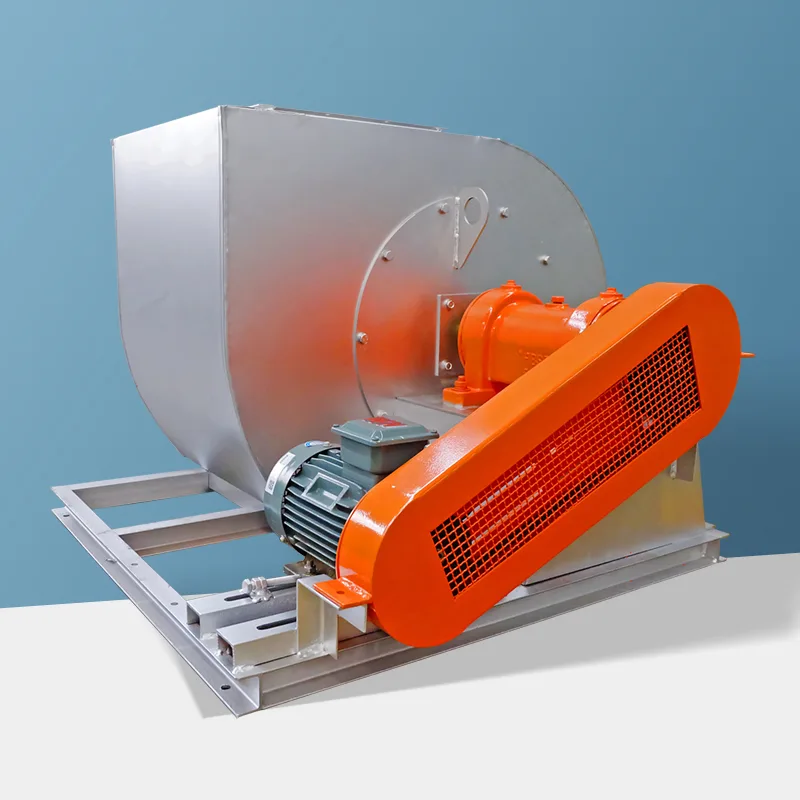

So, together, we have to understand how this particular device works. In fact, during the operation of the facility, it is mainly to convert kinetic energy into potential energy, and then the high-speed centrifugal impeller to speed up and decelerate the steam, change the flow of steam, and then do work. Therefore, for the centrifugal fan, the adjustment of its exhaust air volume May to a large extent interfere with the actual effect of its specific work.

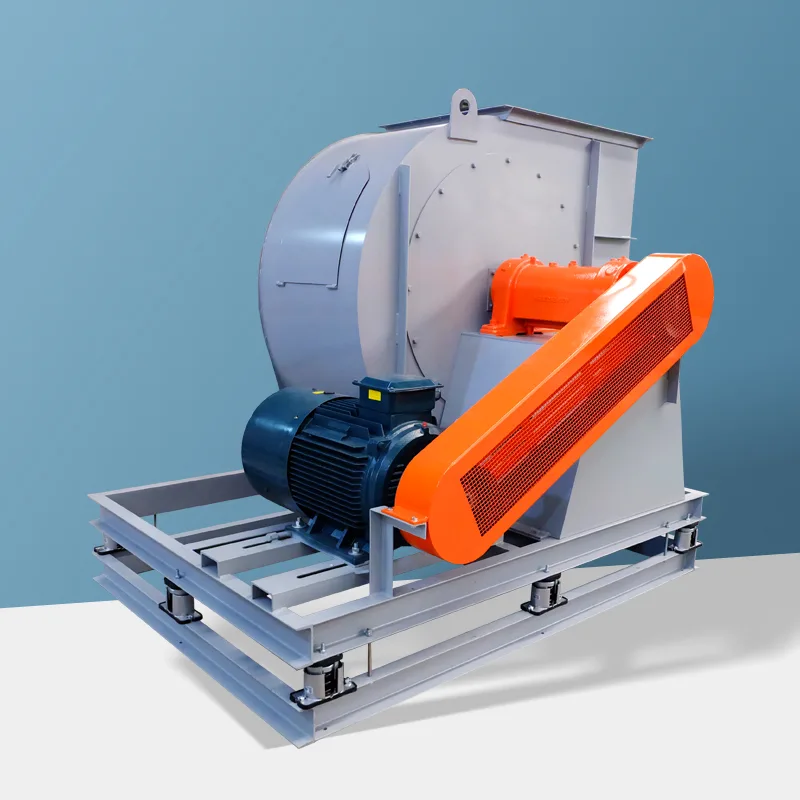

In other words, the whole working process of the centrifugal fan is actually established by the cooperation of many different parts. With the same function of these components, we can really help our consumers. Generally speaking, newly assembled mechanical equipment is easy to produce excessive wind force, so we should control it to make its wind speed effective.

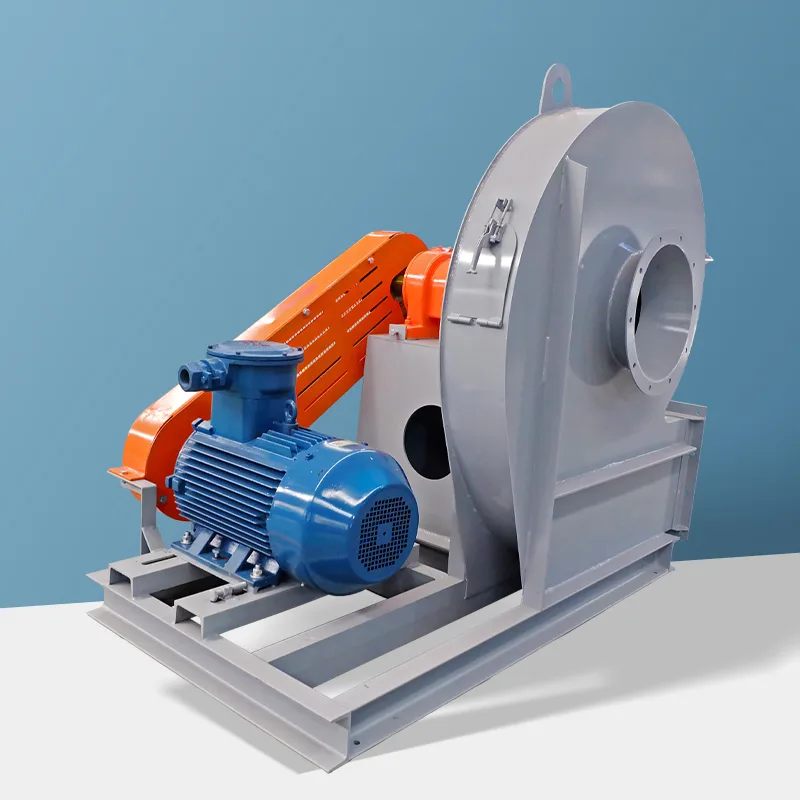

Therefore, whether the volume is too large or too small, should be adjusted immediately. In the case of adjustment, we can use the following methods to achieve the goal: 1 by changing the speed of the centrifugal fan to adjust the total flow; 2. Adjust the opening and closing degree of the control valve; 3. Adjust the resistance coefficient of the pipe network; 4. Remove and replace the centrifugal fan.