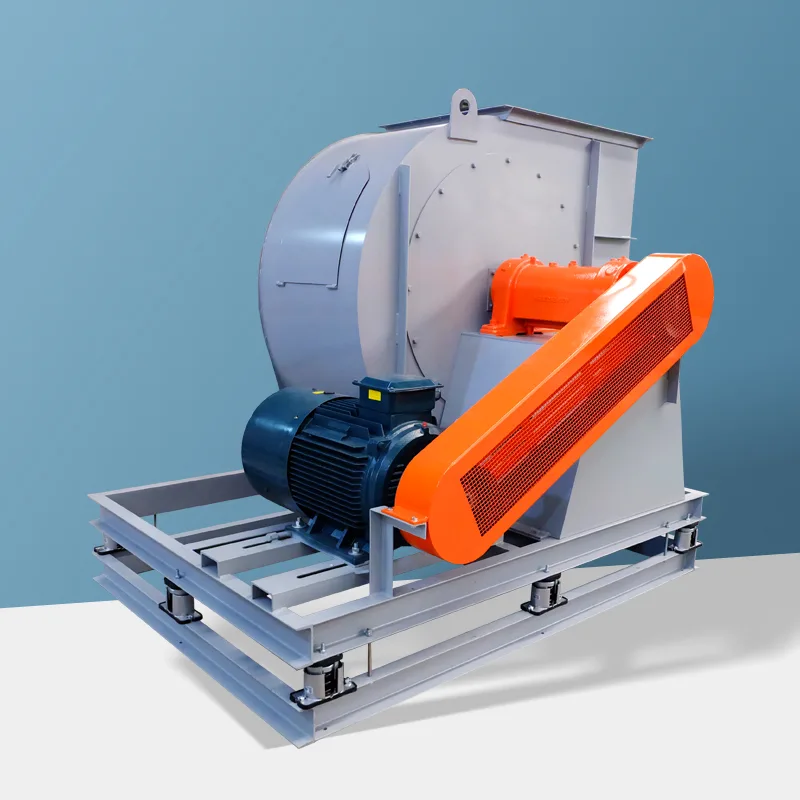

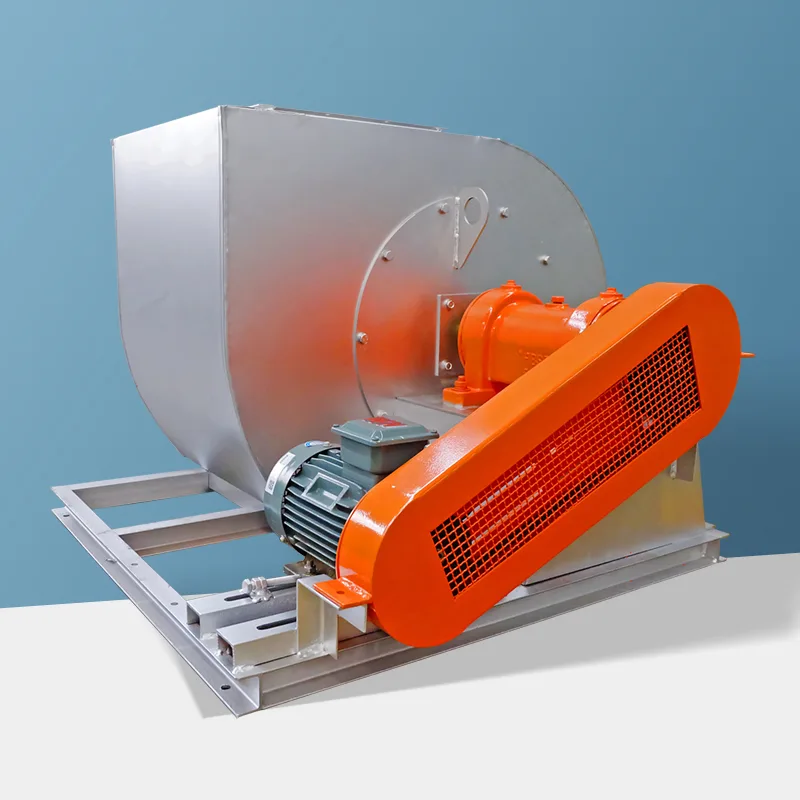

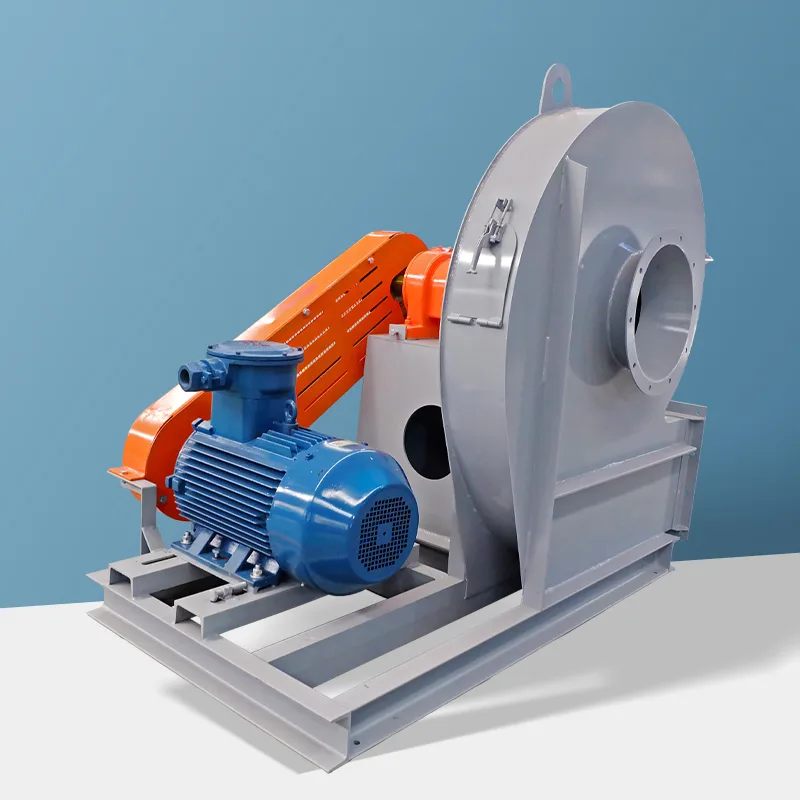

In the use of this centrifugal fan, air flow through the reflow into the next impeller, centrifugal fan can be made into two types: right and left. From the motor side view: the impeller clockwise rotation, known as the right-rotating fan; the impeller counter-clockwise rotation, known as the left-rotating fan. The pressure of high temperature resistant fan is high. Centrifugal fan is made of steel plate, can be divided into one-piece and semi-closed, easy maintenance.

The working principle of the centrifugal fan is basically the same as that of the turbine tightening machine. How about the speed adjustment method of centrifugal fan? Because the gas flow rate is low and the pressure changes little, the furnace centrifugal fan is suitable for the furnace centrifugal fan. Industrial centrifugal fans are excellent for keeping at 95 K. Two measures should be taken to avoid using grain fan powder in places such as dimension: to reduce the heat load of motor, to choose high quality and low consumption raw materials.

According to the trial production results of some motors, the expected aim has been achieved completely. For the convenience of oil injection and lead wire, the oil injection of the fan special motor should lead to the outside of the air duct, the length is basically 1153m between them. According to the practical needs of many projects, the parameters of air volume, air pressure and noise are put forward, which are suitable for a large number of public places and ventilation systems. Centrifugal fire exhaust fan shell top surface marked with the direction of the arrow to prevent reverse installation, to ensure the normal use of exhaust series. Insulation should be designed when cryogenic gases may cause condensation on the shell and pipe surfaces. Therefore, the centrifugal fan needs to control the speed of each fan

The industrial centrifugal fan does not enter the bag filter gas is the circulation fan back dry material grinding, recycling. The effect of the recirculating fan can be to remove material gas, filter dry material, and then recycle back to dry material grinding. How is the speed adjustment method of centrifugal fan discussed? Because the output of cement r & D production line sometimes changes, the air volume of each fan should change with the output change at any time. Need real-time control of the fan volume. The centrifugal fan can achieve the control process and the goal of energy saving and emission reduction, so it is necessary to control the speed of each fan.

With the increasing competition of industrial centrifugal fan manufacturing industry, mergers and acquisitions and capital operation between large and small centrifugal fan manufacturing enterprises are becoming more and more frequent, high efficiency, low noise, long use time limit, reasonable price, must also find qualified manufacturers.