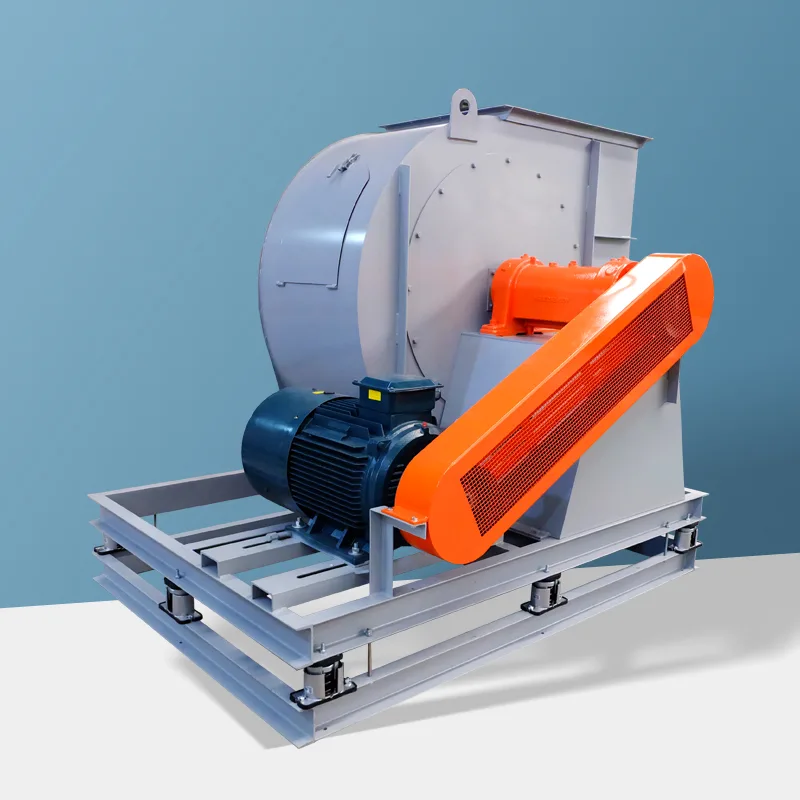

Cabinet type centrifugal fan installation

The cabinet centrifugal fan of the roller bearing assembly line, the different axis degree of the rolling bearing hole on the wall of two rolling bearings, after the motor rotor is installed, can be used to rotate nimbly as the standard.

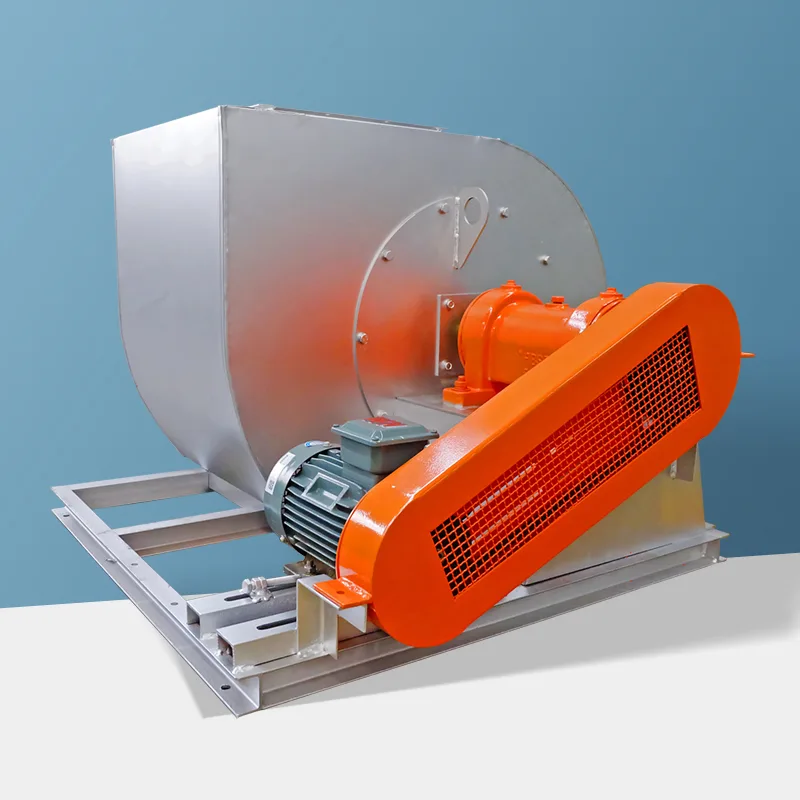

When the centrifugal fan is assembled on site, the cutting surface on the base should be well protected from rusting or operation.

The installation of the integral unit of the cabinet type centrifugal fan should be placed directly on the foundation and leveled with the inclined pad iron.

Before researching and scraping the bearing bush, the rotor axis and housing axis should be corrected, the clearance between impeller and air inlet and the clearance between spindle and the back plate of housing should be adjusted so as to meet the requirements of the equipment technical documents.

Four. The bearing block should be closely connected with the base, the longitudinal non-level degree should not exceed 0.2/1000. . 3/1000, measure the level of the bearing housing with the level meter.

When assembling the fan shell, the axial and radial clearance between the impeller air inlet and the shell air inlet should be extended to the range specified in the equipment technical document, at the same time check whether the anchor bolts are fastened. If the clearance value is not specified in the equipment technical documents, the general axial clearance should be 1/100 of the outer diameter of the impeller, the radial clearance should be evenly distributed, and the value should be 1.5/1000 ~ 3/1000 of the outer diameter of the impeller (take the larger value of the smaller outer diameter) . The adjustment time gap value is smaller to improve the fan efficiency.

When assembling the spindle and bushing, the inspection shall be carried out in accordance with the provisions of the equipment technical documents. The interference between the bearing cap and the bearing bush shall be maintained in the range of 0.03-0.04 mm (measuring the outer diameter of the bearing bush and the inner diameter of the housing) .

Seven. Centrifugal fan assembly of the rolling bearing, two bearing housing on the bearing hole different degrees of shaft, after the installation of the rotor, to rotation flexibility shall prevail.

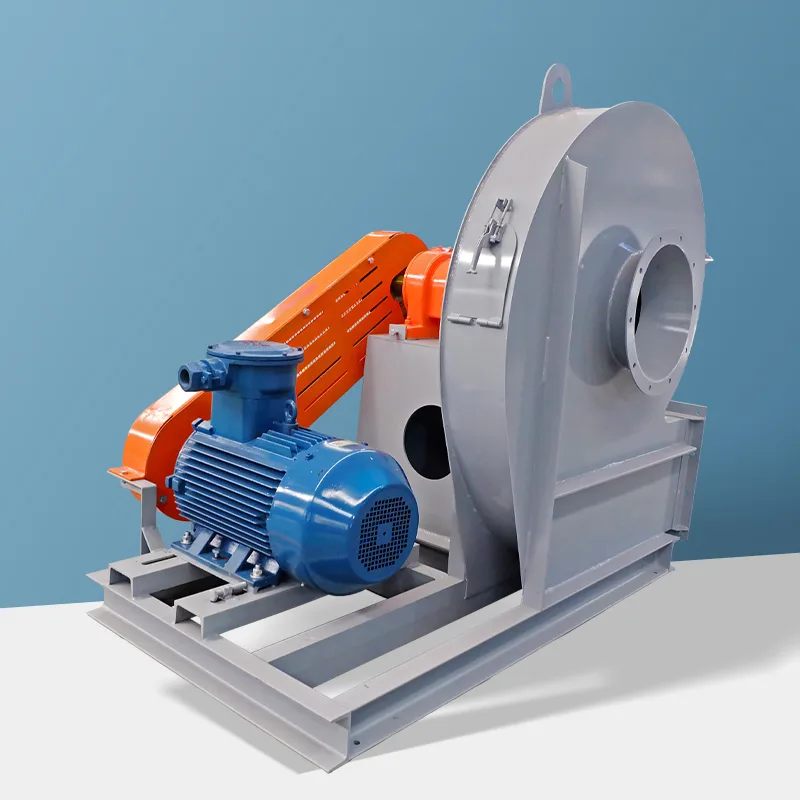

When the fan is aligned, the axis of the fan shaft and the motor shaft are different: the radial displacement should not exceed 0.05 mm, the inclination should not exceed 0.05 mm 2/1000.

For the installation of the integral unit of the cabinet type centrifugal fan box, it shall be immediately placed on the ground basically with the inclined pad iron for leveling.

Filter fan field assembly, base placement to do the ground leveling or sealing gasket solution, there is no skew.

Sufficient indoor space should be set aside around the unit to facilitate installation of the unit. Practical operation and maintenance in peacetime.

Four. When assembling the cabinet-type centrifugal fan shell, the motor rotor pivot line should be taken as the standard to align the shell part, the axial and radial clearance between the air inlet of the centrifugal impeller and the air inlet of the shell is accelerated to the range required by the mechanical equipment technical document.

Low noise cabinet centrifugal fan looking for the engine timing, fan shaft and motor shaft of the different axis: axial precision, determine the displacement can not exceed 0.05 mm, skew can not exceed 0.2/1000.