With regard to centrifugal fans, the following will cover the specific content of the noise levels for centrifugal fans, the classification of common pressures, and the distinction between single and double air intake and their application, mainly for these, let everyone through learning, to enhance the familiarity and understanding of the product.

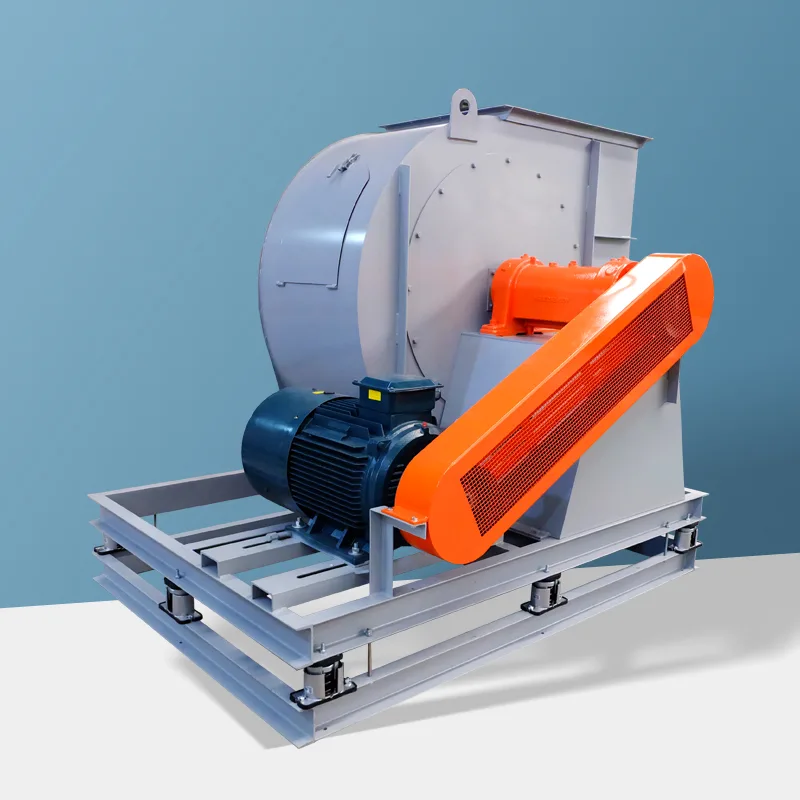

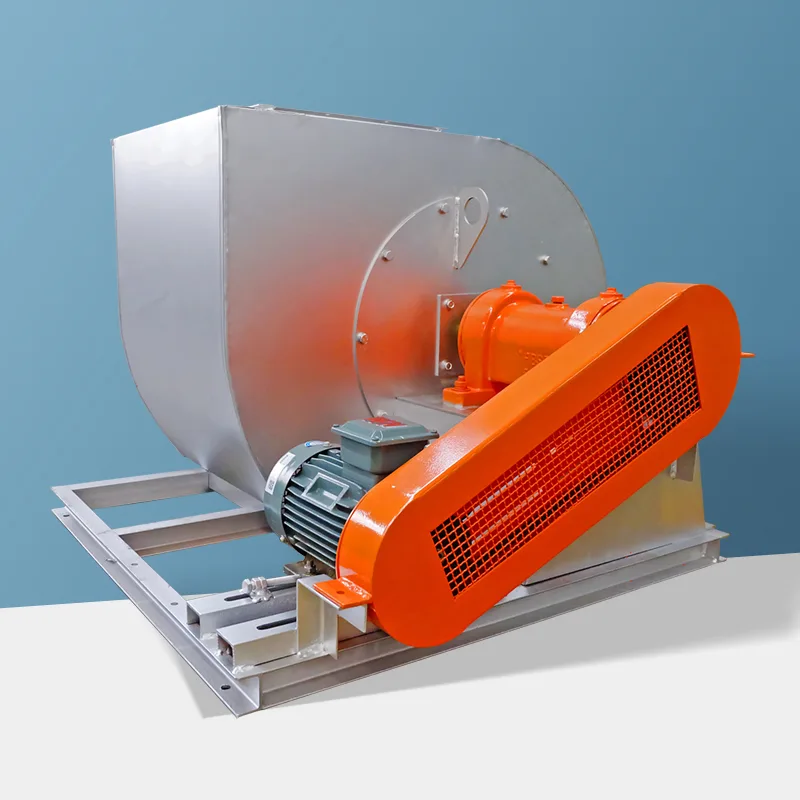

The difference and application of single and double inlet air of centrifugal fan

The single air inlet in a centrifugal fan means that there is only one air inlet and one air outlet in the fan. Therefore, the pressure is relatively high and can be used in the dust removal workshop and the oil fume system. And double air intake, there are two air intakes, one outlet, so, its air volume is relatively large, can be used in the occasion of larger air volume requirements.

The noise level of the centrifugal fan

Centrifugal fan, its noise level, in the relevant factors, mainly has the fan structure, fan working state these two.

Moreover, its working state is determined by the total pressure and the wind volume.

Therefore, different models or different series of centrifugal fans, in the sound level is certainly not the same.

Moreover, even the same model, if in different operating conditions, then the sound level is not the same.

Generally, the noise control method of centrifugal fan is to install a muffler on the inlet and outlet of the fan. If the requirements are high, the muffler and sound insulation box can also be used. At the same time, can be installed between the fan and the foundation shock absorber, thus, to get a good noise reduction effect.

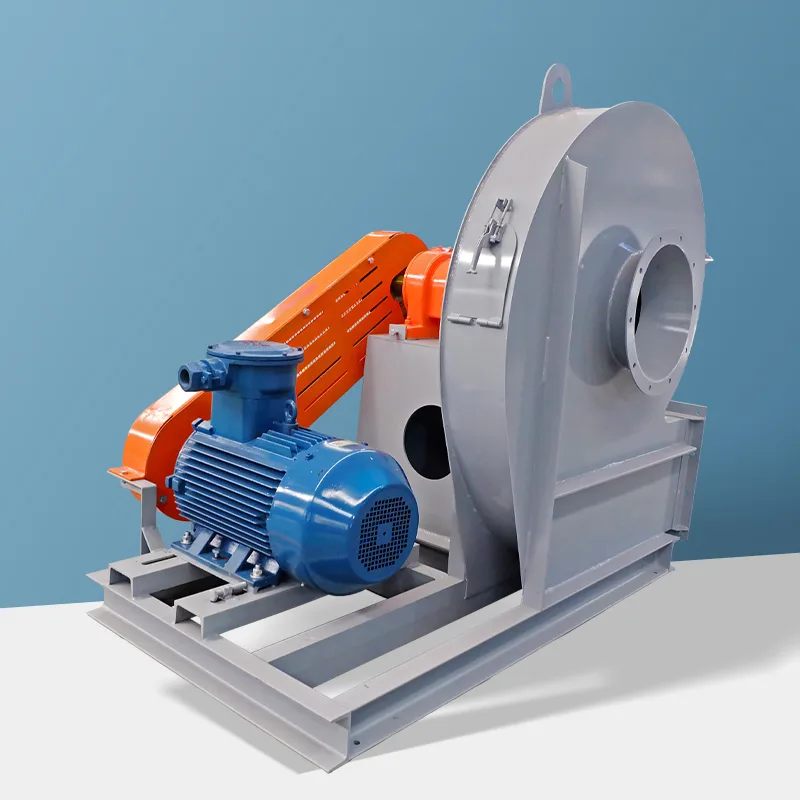

Common pressure categories for centrifugal fans

In the centrifugal fan, in the pressure, its common classification, mainly has the following three:

Low pressure centrifugal fan: the pressure is below 1000PA.

Medium pressure centrifugal fan: pressure is 1000 ~ 3000PA.

High pressure centrifugal fan: the pressure is above 3000PA.