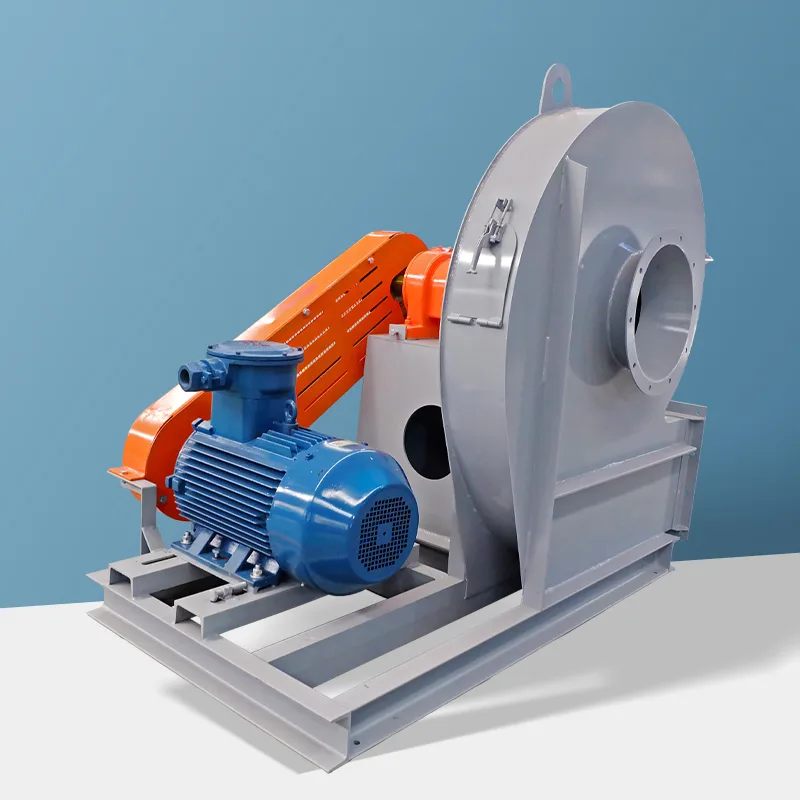

Different measures can be taken to improve the performance of the centrifugal fan. A simpler and more economical approach is to improve the structure of the blade, in effect changing the length of the blade. It should be noted that simply increasing the blade length will lead to excessive centrifugal force, thus reducing the overall coordination of the centrifugal fan.

To solve this problem, the diameter of the impeller should also be increased. In addition, if the blade length increases, the volute size also needs to increase. In this way, the volume of the centrifugal fan will also increase. At the same time, the noise generated by the equipment in the process of operation is bound to increase. Therefore, the blade length should not be excessive increase, and should take appropriate noise reduction measures.

In the process of experimental analysis, it is considered that there is no relationship between the blade length of centrifugal fan and its internal flow characteristics. In addition, to really improve the performance of centrifugal fan, need to comprehensively coordinate its various factors in order to achieve the goal.

In other words, if you change only one parameter of the centrifugal fan, the effect is not particularly obvious. From the test, it can be seen that when the fan blade increases 5% and zero 10% , the work point flow increases 4.9% and 10.5% , the total pressure increases 10% and 22.1% , shaft power increased by an average decrease of 15.7 percent and zero 30.2 percent.

However, we can provide the corresponding reference for the blade modification of centrifugal fan from these data. Moreover, when the blade lengthens, the distance between the impeller and the volute tongue decreases, the rotating noise and the vortex noise increase. At this time can take the corresponding noise reduction measures to improve.

Industry News