The working principle of high-pressure centrifugal induced draft fan is the principle of converting kinetic energy into potential energy. Specifically, when the high-pressure centrifugal induced draft fan impeller in high-speed rotation, the gas is accelerated, and then decelerate, change the direction of the gas flow, so that kinetic energy into potential energy smoothly. In a single-stage centrifugal fan, gas enters the impeller from the axial direction, flows through the impeller and changes its radial direction, then enters the diffuser. Within the diffuser, a change in the direction of the airflow causes a deceleration in the conversion of kinetic energy to pressure energy. The pressure rise occurs mainly in the impeller, and secondly in the diffusion process. In a multi-stage centrifugal fan, the recirculator is used to move the air flow to the next impeller, thereby generating higher pressure.

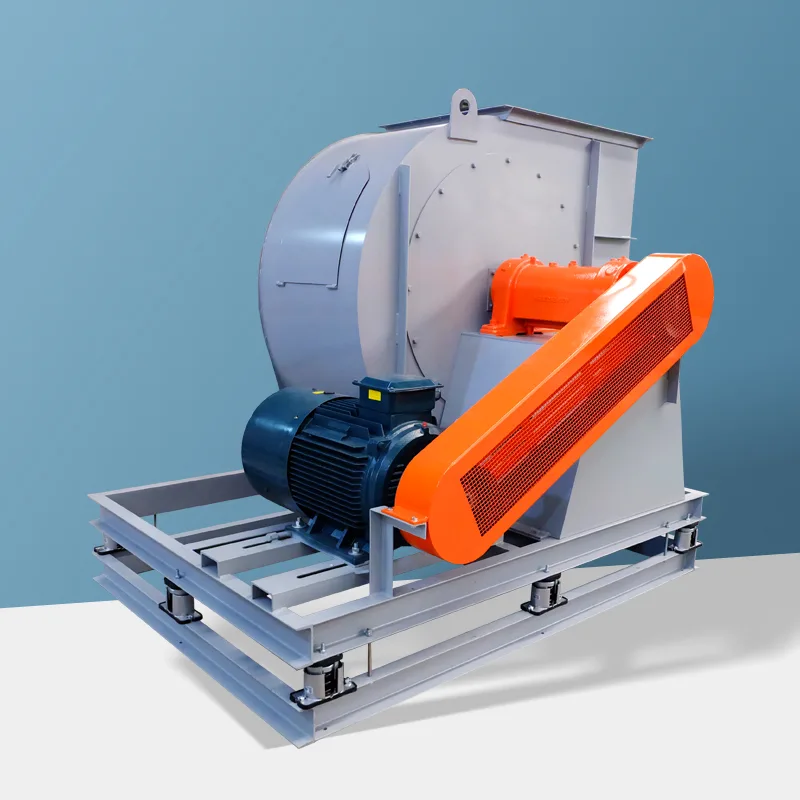

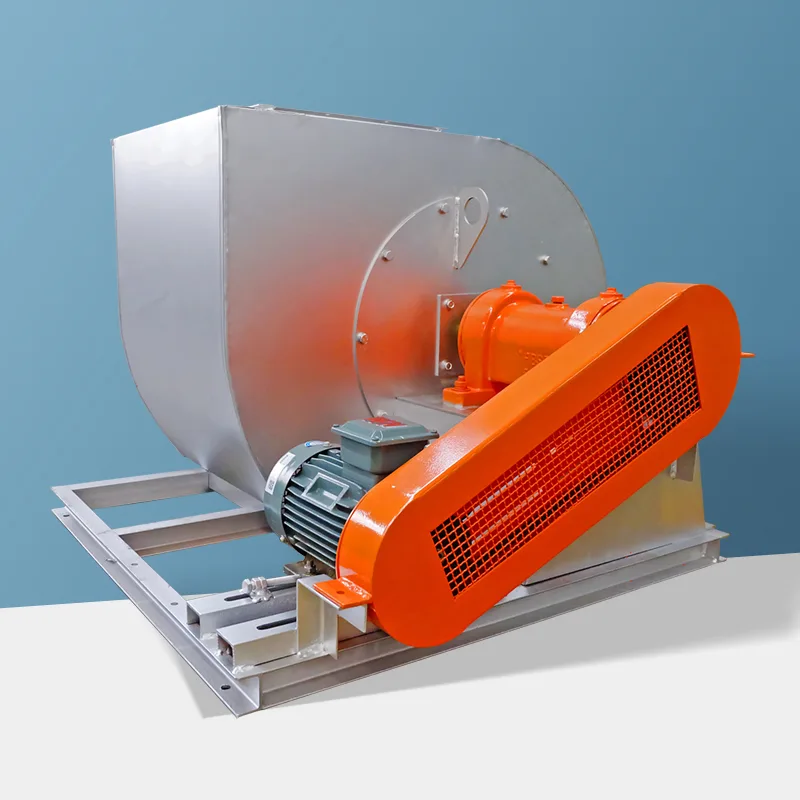

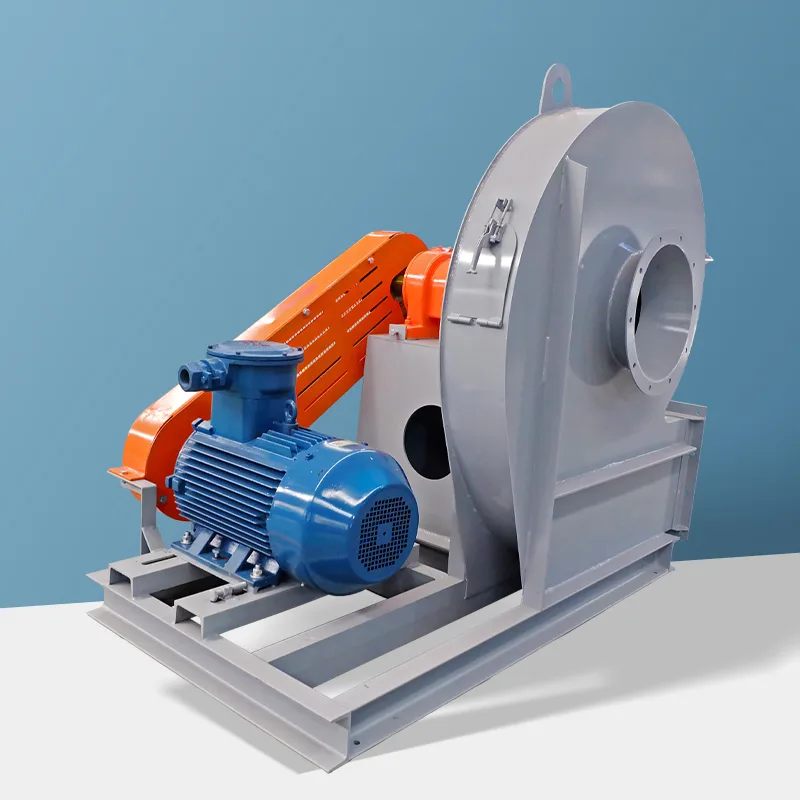

High-pressure centrifugal induced draft fan is mainly composed of casing, motor, rotor, guide vane, Blade, etc. . The casing is the main part of the high-pressure centrifugal induced draft fan, which is usually coated with steel plate to ensure the stability of the air flow in the machine and the isolation of external noise. Motor is an important driving component of high-voltage centrifugal induced draft fan, which can be set to run continuously or intermittently through the motor control device of the high-voltage centrifugal induced draft fan. The guide vane can guide the air flow to the blade, the blade can help the air to accelerate and transfer energy.

To sum up, the working principle of high-pressure centrifugal induced draft fan is closely related to its structural design, which helps to improve its ventilation and atmosphere regulating efficiency in industrial production, thus improve the overall production efficiency and provide operational support for production