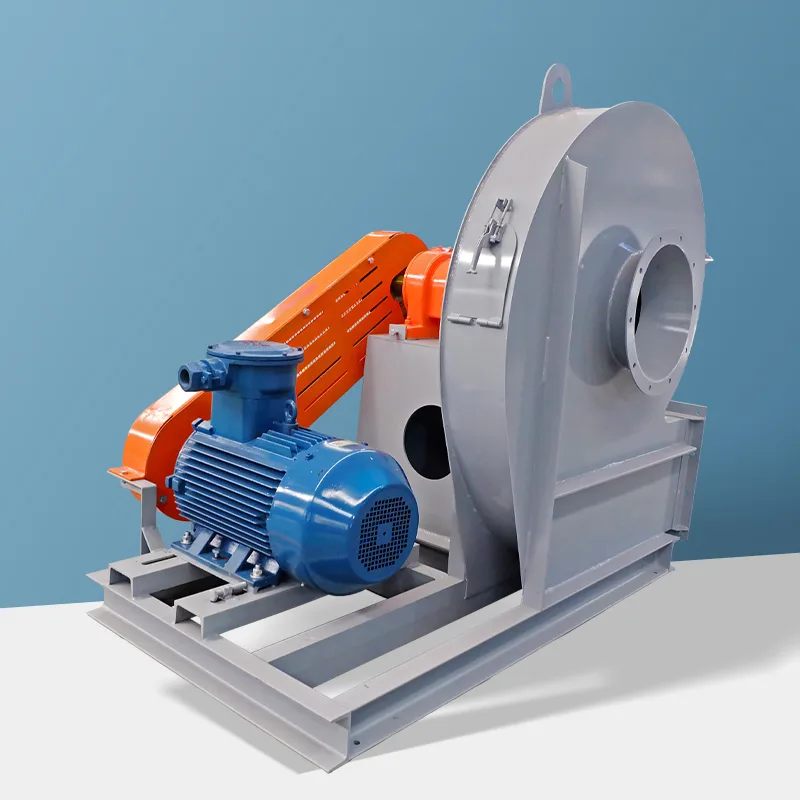

The installation requirement of centrifugal fan triangle belt is very strict

1, belt too tight: will cause frequent belt damage, rear bearing overheating, bearing damage is also the main cause of vibration. If the rotor vibrates, it resonates.

2, the belt is too loose: the friction reduces, the belt slips, causes idling, the power transmission is insufficient, the fan can not achieve the expected effect. The correct installation method should be to use your fingers to press the middle of a belt, the depth of pressure should be between the thickness of one belt and two belt thickness.

Formula: δ = 0.016 L (l: Pulley, center distance mm) requires A, B, C, D three points connected in a straight line and parallel to each other.

3, the triangle belt should have the same specification (batch) . If the length of the same specification is different, they should be the same length. It is strictly forbidden to use one or more belts on the assembly. This will overload other belts and cause them to wear out quickly. It is forbidden to mix the old belt with the new one.

No matter which type of triangle belt is chosen, the type and quantity of pulley should be clearly seen before installation,