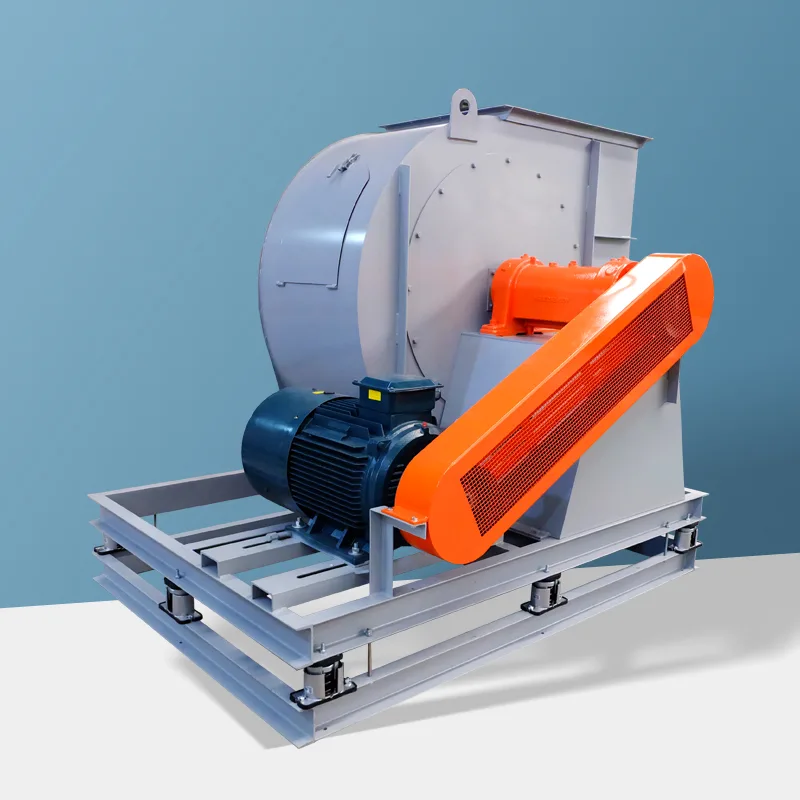

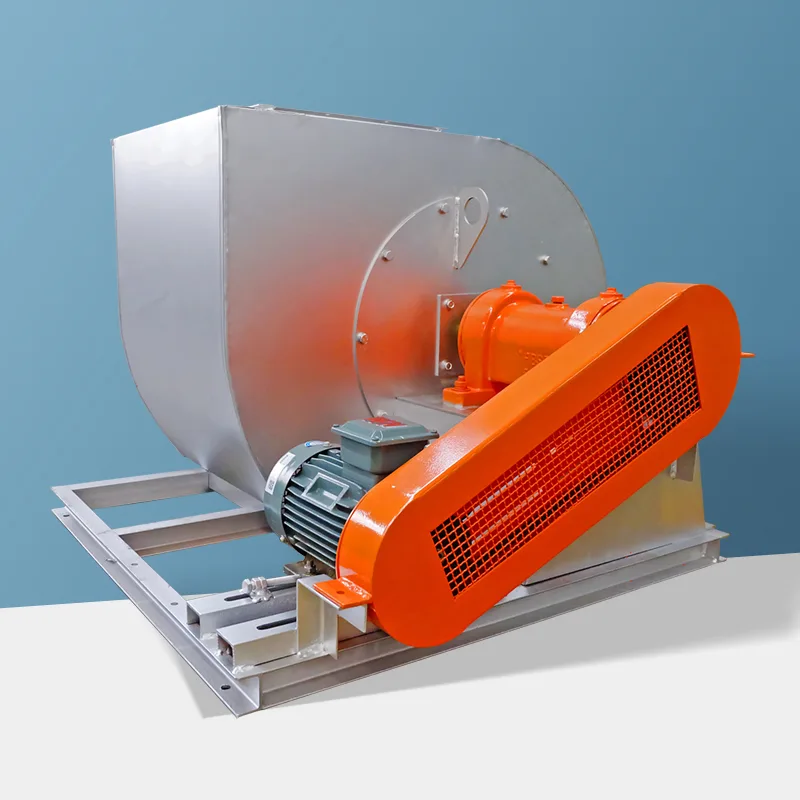

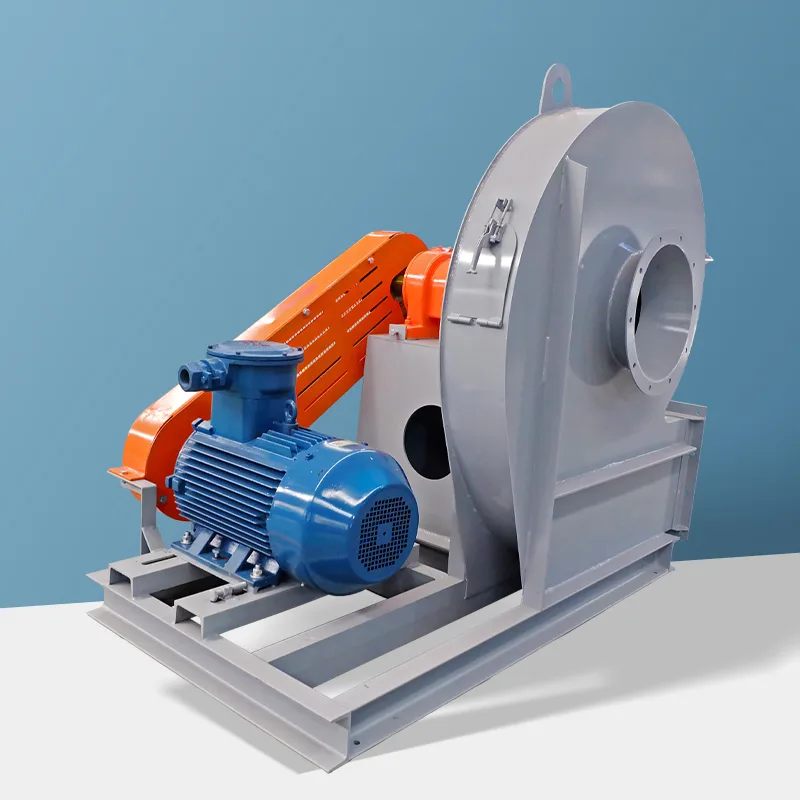

Centrifugal fans are widely used in industrial production and daily life. The centrifugal fan mainly depends on the input mechanical energy to raise the gas pressure and exhaust the gas. It is a kind of driven fluid machinery. Next, let us understand the performance characteristics and working principle of the centrifugal fan.

Features:

The centrifugal fan is essentially a variable current constant pressure device. When the rotating speed is constant, the theoretical pressure-flow curve of the centrifugal fan should be a straight line. The actual characteristic curve is curved due to internal losses. The pressure produced by centrifugal fan is greatly affected by the change of inlet temperature or density. A high intake temperature (low air density) produces low pressure. For a given pressure and flow characteristic curve, there is a power and flow characteristic curve. When the blower runs at a constant speed, as the inlet temperature decreases, the required power will increase the given flow rate.

How it works:

Centrifugal wind energy into potential energy principle, centrifugal fan using high-speed rotating impeller to accelerate the gas, and then decelerate, change the flow direction, will be kinetic energy into potential energy (pressure) . In a single-stage centrifugal fan, gas enters the impeller from the axial direction, the gas through the impeller becomes radial, and then enters the diffuser. In a diffuser, the gas changes direction of flow, causing deceleration and converting kinetic energy into pressure energy. The pressure increase occurs mainly in the impeller, and secondly in the process of diffuser. In a multi-stage centrifugal fan, air flows into the next impeller, producing higher pressure.

Industry News