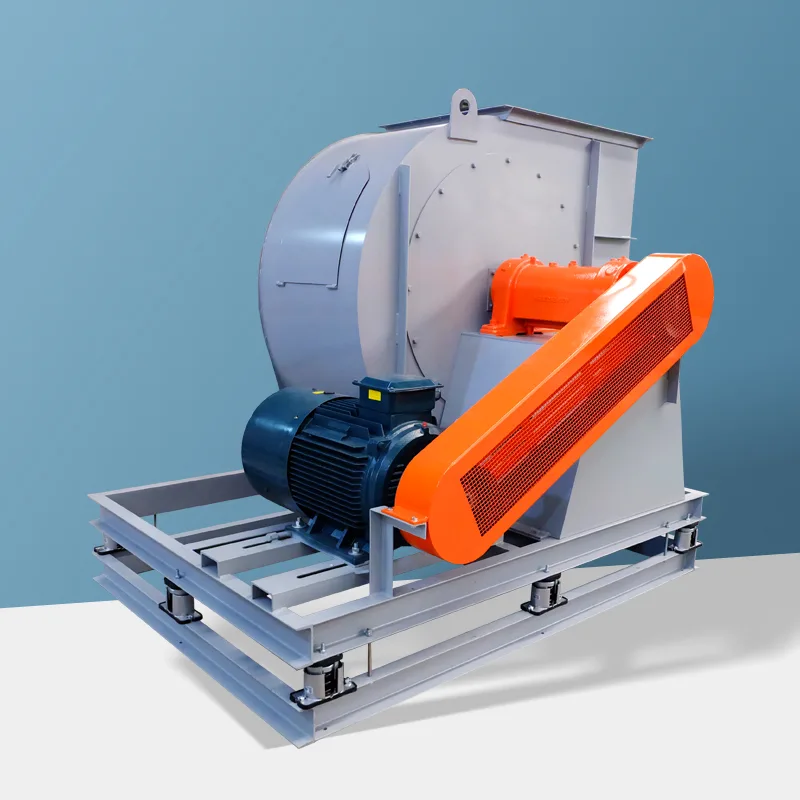

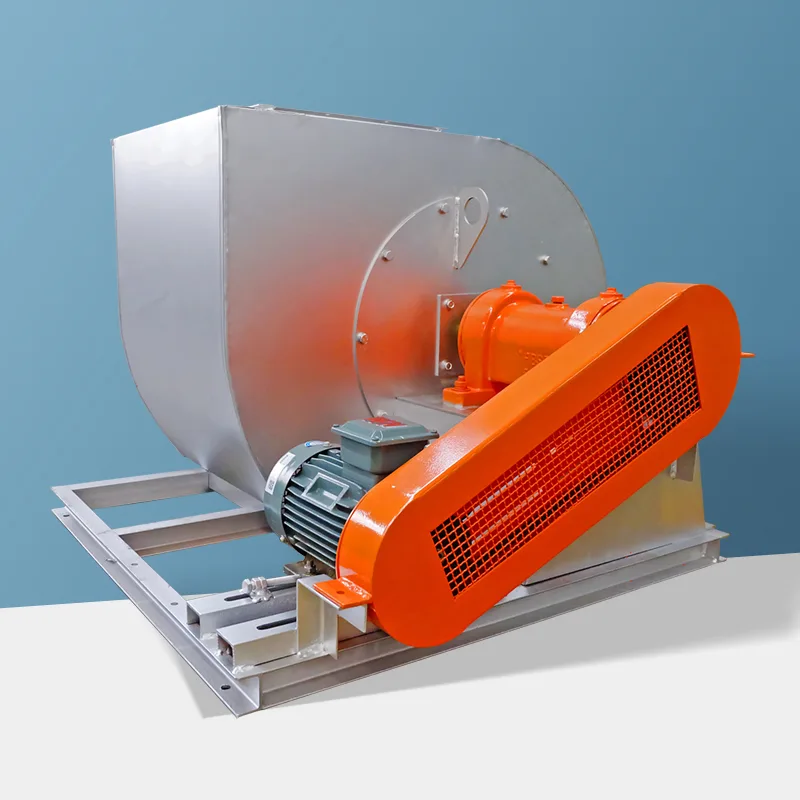

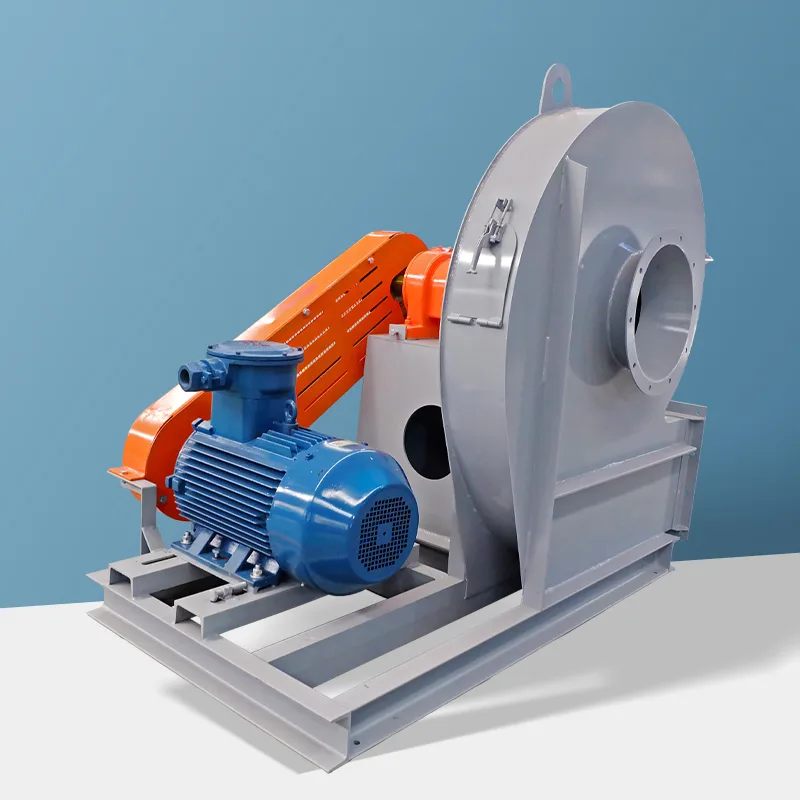

The industrial dust-removing centrifugal fan is a kind of important mechanical prop, which increases the gas pressure by mechanical energy and then discharges the gas. However, if we do not pay attention to daily maintenance, it is easy to lead to industrial dust centrifugal fan blockage, affecting the normal use of equipment. How to maintain the industrial dust removal centrifugal fan?

Bearing maintenance

In the maintenance process, should always check the status of the bearing oil, general at least every six months to replace once, so half a year, check once.

How to maintain the centrifugal fan? These are several aspects that should be paid attention to in the maintenance of industrial dust-removing centrifugal fan. Maintenance personnel should start from these aspects in order to better maintain the machine.

Maintenance of the impeller

The impeller is the rotating part of the centrifugal fan. The straight front plate is composed of a blade, which is composed of an arc-shaped blade with a large radius of curvature. In the maintenance of the impeller, we must check whether the impeller is fixed in the shaft shoulder part, whether the impeller is clearance and damage, must always keep the impeller clean, in the maintenance process, use a wire brush to remove dust from the top of the impeller. If impeller maintenance, must check whether the impeller bolts tightened to avoid impeller off.

Maintenance of the housing

The maintenance of industrial dust removal centrifugal fan should also pay special attention to the location of the shell, see whether the shell and air intake chamber is seriously damaged, whether damaged, especially pay attention to clean up the serious dust deposition, and pay attention to tighten the bolts. If the machine is running unbalance for a period of time, focus on checking the spindle flatness. The connector should be kept clean and the fastening condition should be checked regularly.